Machine vision is the

concept that using machine instead of human eyes to make survey, measurement,

and even judgment. When operating machine vision products, image information

signal is produced from the captured subjects, then delivered to a image

processing system which transformed image signal to digital signal based on the

information such as pixel distribution, lightness, color, and etc. The

processing system generates the related outputs based on preset permissibility

and some other conditions after gathering data of targets including area,

quantity, length, and position from the signals. Different criterions including

dimension, angular, eligibility, have or not can be processed automatically

through the system to determine actions of control devices in application.

A standard industrial vision system consists of light source, lens, camera, image processing unit (or image capture board), image processing software, monitor, and communicating (input/output) unit. For vision inspecting, we focus on needs for inspecting codes and marks from our clients and provide the best marking inspection system. Our unique system offering powerful functions achieving scanning and identifying missing, wrong, and defective codes with different kinds of format. Our system with high processing speed, high degree of accuracy, high satisfaction on size and operation are already helping our clients in all the industries including food, pharmacy, card making, packaging, printing, building materials, and currency producing.

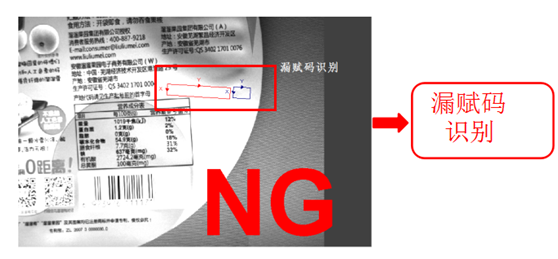

Missing Codes Inspection

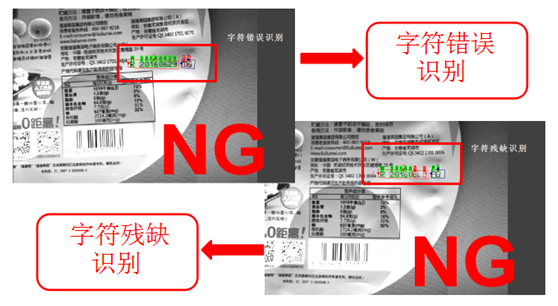

Wrong Codes Inspection

Bar/QR codes Inspection (Content Reading)

Service Tel

010-60219125

Masterful ConsultingBusiness Grade SolutionFlexible ApproachProfessional Service